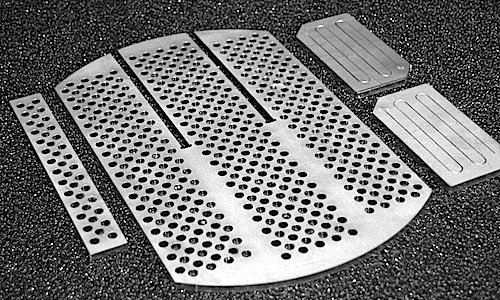

Stainless steel-laser

fabrications-sheet metal fabrication in India Stainless steel creation

supplies us with a surprising cluster of local and mechanical items. The part

of steel fabricators is to take the crude pre-created material and change it

into completed things, from shower plate to cutlery. Go along with us as we

investigate the stray pieces that hold this flourishing industry together.

Stainless Steel Fabrication - A

Potted History

In the times of yore, there were

a wide range of sorts of metal fabricators. The creation of gems, for instance,

has been set up since ancient times. The youngster gems business sector was

less about Bayonne-supported who had destroyed the most tribal adversaries to

claim divine responsibility for hectares of blood-drenched mud. It additionally

required minimal more aptitude than the capacity to gouge and bite gold into a

head-sized ring. In any case, as metal manufacture (and mankind) advanced, it

turned out to be perpetually modern and specific. Methods to build the

immaculateness, solidness and quality of such items were produced.

At that point there were articles

like chains, bolts and keys, also parts for machines, for example, attack

motors, portcullises or even instruments of torment. While these all required

an enormous assortment of creation abilities, the reach and nature of items is

little contrasted with the endless cluster of items made fabrication. Stainless steel-laser

fabrications-sheet metal fabrication in India

Stainless Steel Fabricators:

Experts and Specialists

Given stainless steels

omnipresence in cutting edge industry, horticulture, engineering, cordiality

and in homes over the world, the advanced metalworker truly should be a

handyman to get a handle on the mind blowing scope of ventures served by this calling.

Luckily, with the mechanical

upheaval came specialization, decreasing the learning required. Nowadays, the

best fabricators know how to make particular sorts of remarkable and persisting

items for every client, furthermore know the most ideally equipped steels for

the current task. This division of work - to utilize a term you may commonly

hope to get notification from dreadlocked, Marx-gushing understudies - gives

key detail to the contemporary client. For instance, an auto is an auto,

however you wouldn't take a Toyota issue into a Mercedes carport, okay?

Stainless steel fabricators know their items, their clients, and the backing

that is required after the deal. Undoubtedly, they need to know this in a

business sector that requests skill and master information. Stainless steel-laser fabrications-sheet

metal fabrication in India

The essential purpose behind this

is such items will endure forever. It is utilized as a part of the development

of structures that are intended to continue eras of weathering, and in

apparatuses that must withstand many years of work and grating. It is utilized

to make sterile, non-receptive holders for conveying everything from purged

drinking water, through perilous destructive materials, to sewage and waste

items. It is utilized as a part of labs, shower units and kitchens. On top of

that, these items never chip, break or rust. Ever ask why Superman was known as

the Man of Steel? Stainless steel items are near on indestructible, and also

being hygienic and financially savvy.

A vast greater part of steel

creations are totally bespoke, being customized to the customer's particular

necessities. Such fabricators appreciate a working relationship that is more

much the same as an association than to that of client customer. Given that

they will make an exceptional item that will endure forever, it is in light of

a legitimate concern for both sides to convey nearly. Stainless steel

fabricators are knowledgeable in the generation viewpoint, as well as the

issues encompassing establishment and upkeep. Stainless steel-laser

fabrications-sheet metal fabrication in India

Any fabricators worth their salt

will have the capacity to give the customer a certification based around center

standards. These will identify with the way that bespoke requests are a

substantial piece of stainless steel manufacture, which implies that ventures

arrive in an enormous scope of shapes and sizes. As mechanical methodology

advance, or forms in family unit feel change, those in stainless steel

manufacture must adjust to suit the changing needs of their clients. The

customer needs an accomplished group that can work through the occupation with

them, taking into account their one of kind necessities and giving close

consideration regarding every phase of the undertaking. A top producer in the

business will have a group with incredible experience and a notoriety that has

been built up over years, if not decades. They will take the item from origin,

and experience all the essential stages from cutting and molding of pre-fab

materials, through altering and welding, to the completed and cleaned item, at

the same time keeping up discourse with the customer to guarantee that the

occupation meets the most noteworthy guidelines and quality. From beginning to

end, stainless steel creation ought to be an activity in tender loving care and

client care.